Decentralised versus Centralised Manufacturing Models

In the highly competitive global market of today, the need to provide highly customised products that are managed throughout the product life cycle. This is causing companies to rethink their manufacturing strategies.

With the emergence of new manufacturing technology, companies of all sizes can adapt in order to succeed and the decision for some to migrate from centralised manufacturing to decentralised plants is critical to that success.

What are Centralised and Decentralised Structures?

Centralised manufacturing involves a single factory or location that can alleviate per unit production costs by employing versatile and adaptive equipment. In a centralised structure, the business can benefit from economies of scale and consistency in their processes. In short, it means you can produce different products or quantities of items based on demand and scale. In a centralised structure raw materials are processed through a central warehouse to a manufacturing facility and typically flow into a distribution centre.

Decentralised manufacturing involves an organisation with multiple facilities or locations with the ultimate goal to provide service or coverage for large areas. As opposed to a central location, the factories or distribution centres are spaced out across a wider area. Raw materials can be procured locally, and warehouses are centred around distribution to local customers. These locations are generally positioned close to customers and have a higher degree of flexibility within their product and process offerings.

Figure 1: Centralised vs Decentralised Structure (Kendrick, 2017)

Advantages of a Decentralised Manufacturing Model

Due to the geographic diversity of Australia, a decentralisation model provides several advantages. Companies with decentralised manufacturing enjoy many benefits that often elude companies with centralised plants. Current manufacturing trends show that more and more companies are choosing a decentralised manufacturing strategy. The benefits of decentralisation are as follows.

1. Greater Flexibility

The smaller facility size means that the manufacturers have a generally flat structure that is close to customers. This tends to enable greater agility, more flexibility and better and timelier information communicated both within the organisation and externally. Communicating on a regional basis is more efficient than having to go through multiple channels at a single corporate office. This means decisions can be made quickly. Additionally, having replicated sites provides inherent redundancy into the business both from a human and physical capital perspective. This reduces risk associated with site specific adverse events.

2. Greater Customisation

Greater flexibility in manufacturing processes means greater opportunities for customisation. A company with decentralised manufacturing can manufacture products that are in demand in a specific region. As they are physically located closer to the customer, with a shorter feedback loop, the opportunities for product design optimisation to meet localised consumer demand (and potential for regional customisation) are increased. When a company is physically close to its customers, it can be more flexible in meeting increasingly diverse demands. The decentralised structure also results in more manageable distribution channels that are physically closer, providing the conduit between the manufacturing plant and end-user which is crucial for customer-led innovation.

3. Reduced Operating & Logistics Costs

It enables the business to be positioned closer to the customer, which results in simpler logistics and timelier delivery of goods. Production facilities can distribute products to customers quickly, as shipments have a shorter distance to travel. Additionally, due to the decentralised structure, plant managers are given more authority to implement their own procedures for maximum efficiency. In some cases, raw materials can be purchased locally which can result in reduced cost. Cost reduction can also be found in some cases due to low labour costs in some regional areas. The general flexibility with regards to location selection results in the ability to strategically select raw materials, location site and staff based on what is most economically viable for the business.

4. Increased Jobs and Skills in the Regions

The structure also enables the decentralisation of the skills and jobs required to deliver the products. It means that locations can be selected based on the regional need for upskilling, training, and levels of unemployment. Manufacturing creates highly skills, long term, stable employment which can be highly beneficial in regional areas. This structure enables localised maintenance and service staff to be upskilled in regional areas to support their local customer base. Additionally, it creates opportunities for the regions to diversify their industry and skills base.

5. More Motivated Staff

A decentralised structure has been shown to create more motivated managers and employees, according to a study by Harvard University, decentralised manufacturing actually increases motivation and creativity by giving lower-tier managers more responsibilities. When a manager is given a sense of ownership over an operation, efficiency increases among employees in both production and support positions. (Malone, 2004) As a result, this can encourage those who are more entrepreneurial to use their talents to achieve results. These managers may take a sense of ownership into their operations, which can help increase efficiency among employees in both production and support positions. Highly motivated managers may also be more creative in solving problems and finding solutions. (Suttle, 2021)

6. Enables Product Stewardship

Manufacturers have a social responsibility to ensure that they manage their product throughout its product life cycle and enables simplified end of life recycling. Everyone who imports, designs, produces, sells, uses and disposes of products has a shared responsibility to reduce the environmental and human health and safety impacts of those products. (Government, 2021) A decentralised structure enables good product stewardship. This structure allows manufacturers to service, repair and maintain the product using local technicians. This which is critical for a geographically diverse state like Queensland where it is not always practical to fly in the maintenance staff from a centralised location. This structure enables not only efficiency in logistics when the product is first manufactured, but also means when the product reaches its end of life, it is located close to the manufacturing facility for recycling and repurposing. Additionally, the technical skills required to assemble, service and maintain the product are generally the same skills required to disassemble and recycle and reuse the components within a product. This is a strong benefit of a decentralised structure.

Disadvantages of a Decentralised Manufacturing Model

1. Increased Capital Start-up costs

A decentralised model is made up of a number of locations and facilities. As a result of this, the initial capital investment required to establish multiple facilities is typically greater than that of a single central facility.

2. Increased Regulatory Burden

Additionally, as there are multiple sites located in multiple Local Government Areas, regulatory approvals and safety and environmental requirements must be assessed and managed for multiple sites. This can increase both the cost of operations, and the lead time for facility establishment.

3. Increased Per Unit Costs

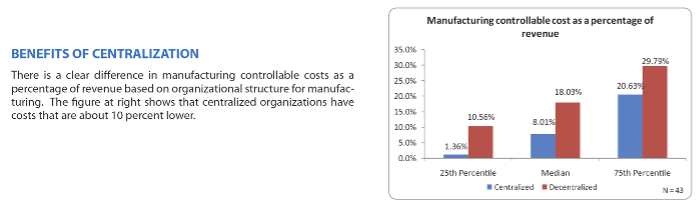

Figure 2: American Productivity & Quality Council (APQC, 2010)

Centralised organizations have 3 percent lower manufacturing costs than decentralised companies. (Today, 2016) These per unit costs tend to be higher, because the business is not mass producing a single good from one plant and you don’t get the economy of scale you get with a larger volume facility. Often this also means that the return on investment may not be achievable to justify investment in automation and robotics if volumes remain low in multiple facilities. According to the American Productivity & Quality Council centralised organisations have controllable costs that are about 10% lower than decentralised organisations.

4. Challenges with Consistency & Production Forecasting

Consistency in products and processes may suffer because of the decentralised nature of the operations. Multiple locations filled with their own hardware and personnel may result in process variation. Centralised manufacturing provides better product forecasting and consistent production schedules as the peaks and troughs of regional sales can be balanced in a central facility.

Hybrid Manufacturing Model

As outlined above there are demonstrated benefits and disadvantages of a Decentralised Manufacturing Model. In practice, it would be ideal if a balance could be reached where a business could realise the benefits of both models with a Hybrid Manufacturing Model.

Common practice is to begin with a single, centralised location when the company first launches. As demand grows, that coverage can expand into new regions and locations, transforming a once centralised structure into a decentralised one. Often, a company will decentralise to meet increased demand or to enter alternate markets and coverage areas.

Additionally, it is important to note that just because there are economies of scale in one part of a process doesn’t mean that the whole process has to be centralised. A hybrid model can be employed where you can get the benefits of both bigness and smallness by centralising only those decisions involving important economies of scale and decentralizing everything else. (Malone, 2004)

Overall, decentralised manufacturing is best suited for companies that have easy to process goods with demand spread evenly across larger areas. If your company is smaller with a local customer base, or has incredibly unique or highly specialized products, then centralised operations are better.

Bibliography

APQC. (2010, April 25). American Productivity & Quality Council . Retrieved from Benefits of Centralization: https://www.apqc.org/

Government, F. (2021, June 1). Product stewardship in Australia. Retrieved from Australian Government Department of Agriculture, Water and the Environment: https://www.environment.gov.au/protection/waste/product-stewardship

Kendrick, B. (2017, February 1). Strategies to realize decentralised manufacture through hybrid manufacturing platforms. Retrieved from Science Direct : https://www.sciencedirect.com/science/article/abs/pii/S073658451530137X

Malone, T. (2004, March 29). Making the Decision to Decentralize. Retrieved from Harvard Business School: https://hbswk.hbs.edu/archive/making-the-decision-to-decentralize

Suttle, R. (2021, June 1). The Advantages of Decentralised Manufacturing. Retrieved from Small Business Chron: https://smallbusiness.chron.com/advantages-decentralised-manufacturing-33971.html

Today, I. (2016, July 26). Centralised vs Decentralised Manufacturing. Retrieved from Industry Today: https://industrytoday.com/centralised-vs-decentralised-manufacturing/